Known for their innovativeness, Hauri's process engineers came up with a concept to save energy in their grinding-drying process. In cooperation with Maerz Ofenbau AG, a system was developed that makes it possible to channel all the waste gases from the PFR kiln into the grinding-drying plant. By using the waste heat, about 3.5 million kWh of natural gas or, in other words, about 600 tons of CO2 can be saved annually.

Maerz Ofenbau AG has accompanied the project from the beginning and supported Hans G. Hauri KG with engineering, material supply and personnel for the commissioning. In order to maintain the high safety level of the existing plant, Maerz Ofenbau AG prepared a risk analysis for functional safety in the first phase. The results of this analysis were then incorporated into the design of the process and measurement technology as well as the control of the plant.

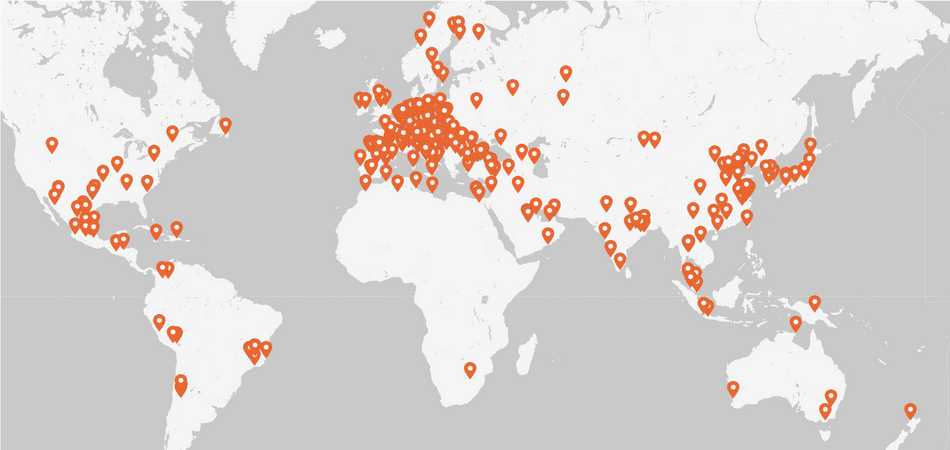

With Maerz, you have a strong partner for your conversion and revamp projects. Interested? Contact us!