Applications of lime

Lime is used in many ways.

You may come across it more often than you think.

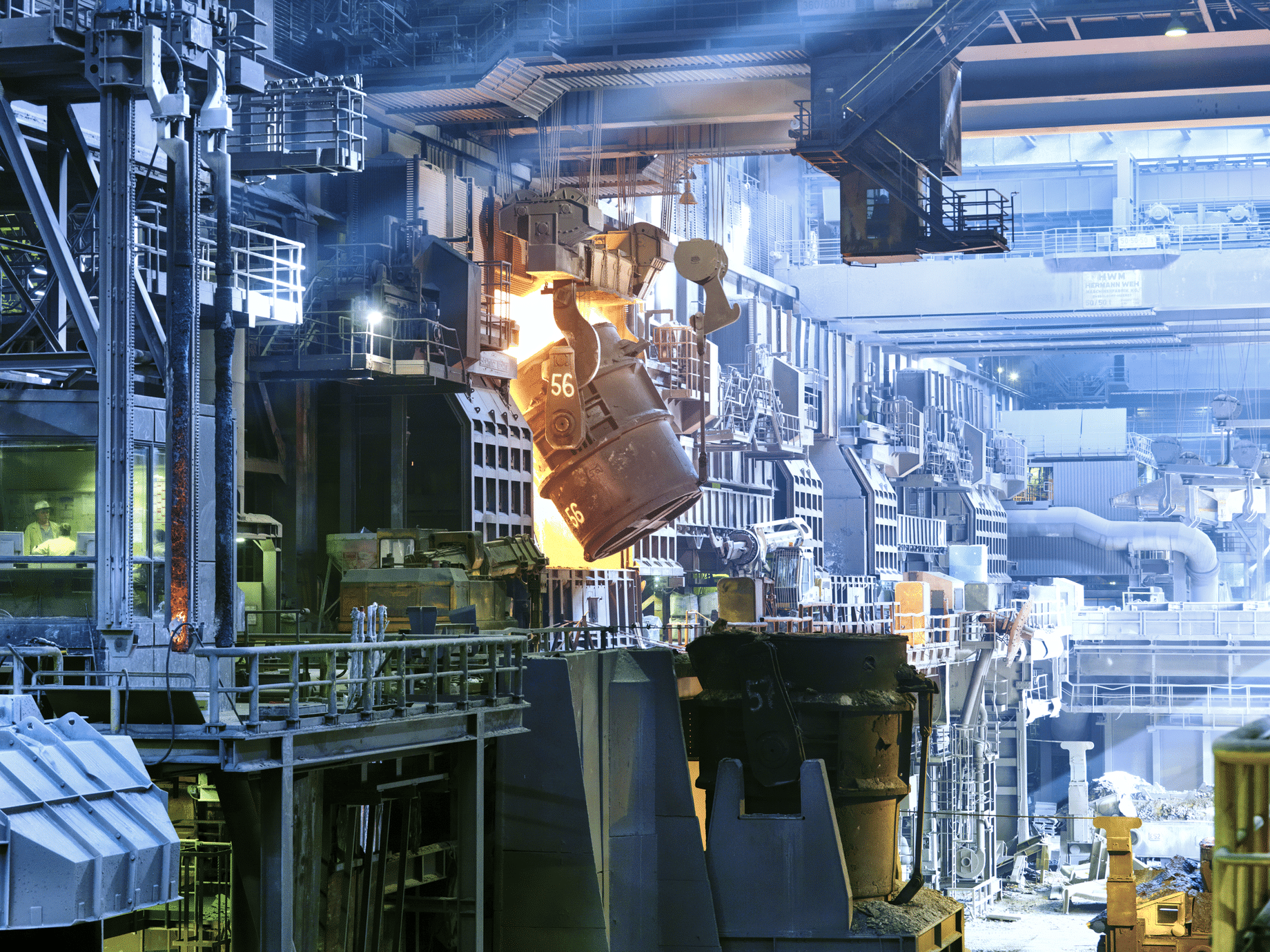

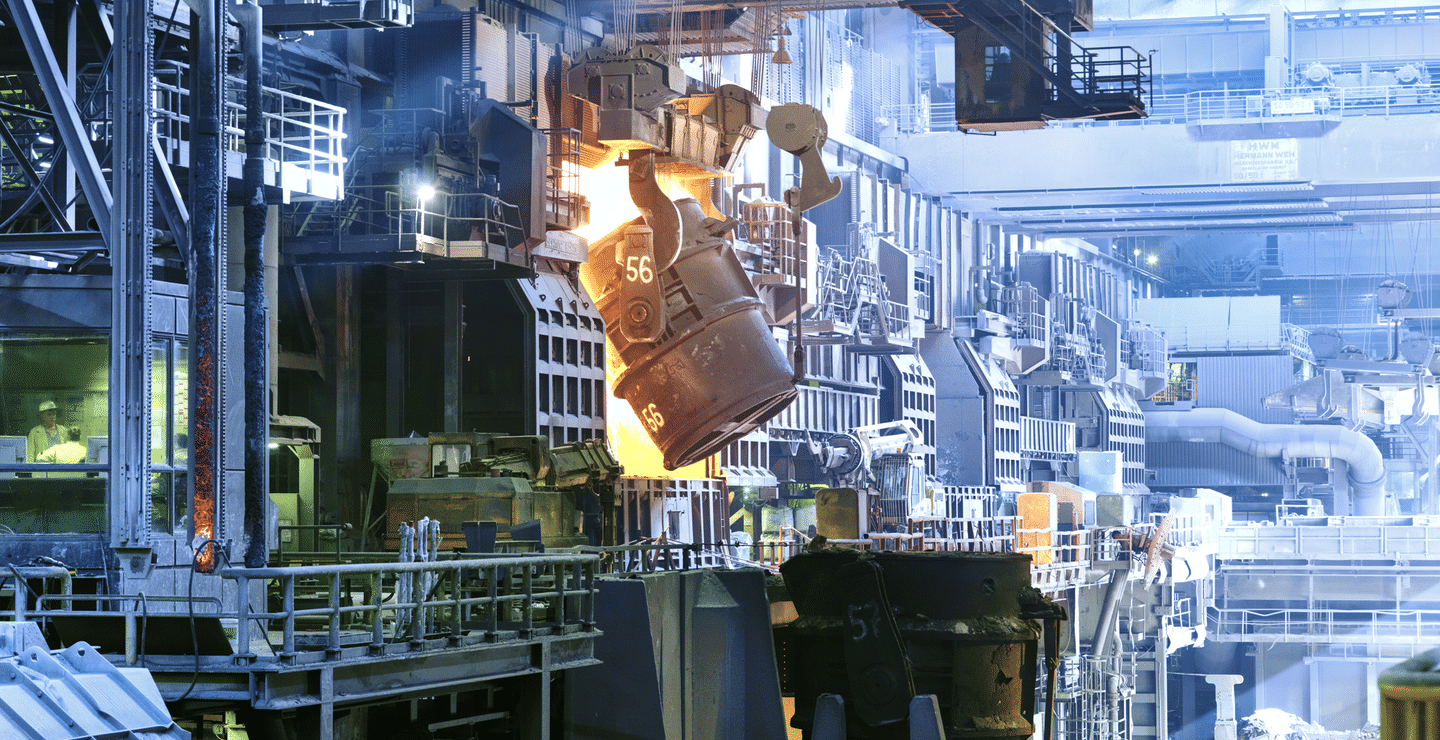

The largest consumer - the iron and steel industry

Without lime there would be no iron and no steel. And without steel, our society would not be able to live today. Lime plays an important role in several process steps in the steel industry: one essential application is the production of pig iron. Here, lime is used as an additive for the sintering of ores before they are melted in the blast furnace.

In many cases, the pig iron from the blast furnace has to be desulphurised. Lime is also needed for that. It is ground and injected into the molten pig iron in the torpedo ladles, and only then can the pig iron be processed further.

In a further step, steel is produced from the pig iron with the help of the oxygen blowing process (converter technology). The high reactivity of quicklime from a Maerz PFR kiln makes it the predestined additive for the formation of slags, which absorb all impurities from the pig iron.

Lime is also added to the melting process in the electric arc furnace as a slag-forming agent when scrap is melted down in an electric steel plant.